PLC control steel roof tile making machine

Basic Info

Model No.: ZM-900

Product Description

PLC control steel roof tile making machine

PLC control steel roof tile making machine is one machine that controled by PLC,It is easy to operate and can produce steel roofing sheets depend on the profile drawing ,the normal feeding width of it is 1000mm ,1200mm,1250mm,adn we can also design depend on your requirement .and you can also provide your specification of the machine ,we will give you a satisfied offer

There are also double layer roof roll forming machine ,floor deck roll forming machine and CZ purlin roll forming machine etc for you to choose

Specifications:

Feeding material: PPGI steel coils

Thickness of the plate:0.3-0.8mm

Feeding width:1000/1200mm

Machine size: 6200mmX1700mmX1400mm

Diameter of the axle :donwn-Φ80mm/ up-Φ90mm

Rolling material: 45#

Rolling galvanization thickness:0.05 mm

Rolling stages:14-15 stages

Productivity:10-12m/min

Total power:5.5kw +3kw

Voltage:380V 60Hz 3phase or as requirement

Weight:about 4.5T

Base frame:350H steel

Side board thickness:16mm

Cutting blade: Cr12 with heat treatment

Cutting system: Hydraulic cutting system after forming

Control cabinet: PLC and frequency changer in it

Warranty:12 months limited warranty

Delivery: 30 days after receipt of advance payment

Package: Plastic packing and nude in the container

Payment Term: T/T, L/C, Trade assurance

Images:

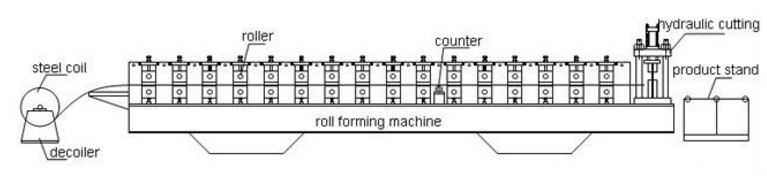

Produce process flow

Components

1. Cutting Mechanism

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut , Post cut

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

It adopts Taida PLC to control(can make as your requirement). The target piece length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one.

5. Manual un-coiler

6. Recieving table

Main framework adopts welded steel and supported roller, and used for transmit and collect the finished products.

Packing&shippment

Contact

Product Categories : Roll Forming Machine > Single Layer Roof Roll Forming Machine